What are the performance analyses of titanium anodes?

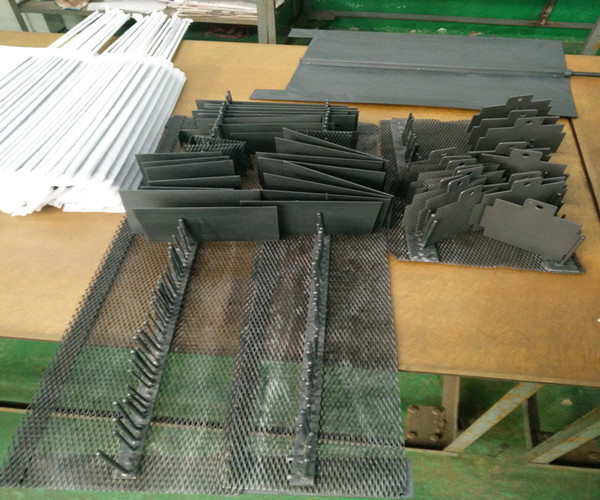

Titanium anode have iridium oxide coated titanium anodes,mixed metal oxide coated titanium anodes,platinised titanium anodes,titanium anode mesh and titanium anode plate.See below for the performance of titanium anodes.

1. Low temperature resistance,platinum titanium anode.

The low temperature resistance of the titanium anode is better, and its strength increases with the decrease of temperature, but the plasticity change is not large. In addition, the titanium anode can still maintain good ductility and toughness at low temperatures of -196-253°C, avoiding the cold brittleness of metals, and is an ideal material for cryogenic containers, storage tanks and other equipment.

2. Heat resistance

The new titanium can be used for a long time at a temperature of 600°C or higher.

3. Anti-damping performance

Titanium anode has high anti-damping performance. After metal titanium is subjected to mechanical vibration and electrical vibration, its own vibration decay time is relatively long compared with steel and copper and other metals.

4. Non-magnetic and non-toxic

Titanium is a non-magnetic metal and will not be magnetized in a large magnetic field. It is also non-toxic and has good compatibility with human tissues and blood, so it is adopted by the medical profession.

5. Inhalation performance

Titanium is a very active metal with chemical properties. It can react with many elements and compounds at high temperatures.

6. Corrosion resistance

Titanium is a very active metal, its equilibrium potential is very low, and the thermodynamic corrosion tendency in the medium is high. In the air or in an oxygen-containing medium, a dense, strong adhesion and inert oxide film is formed on the titanium surface, which protects the titanium matrix from corrosion. Even due to mechanical wear, it will quickly heal itself or regenerate.

7. Good heat transfer performance

Although the thermal conductivity of metallic titanium is lower than that of carbon steel and copper, the wall thickness can be greatly reduced due to the excellent corrosion resistance of titanium, and the heat exchange method between the surface and the steam is dropwise condensation, which reduces the thermal resistance. No fouling can also reduce thermal resistance, so that titanium has better heat transfer.