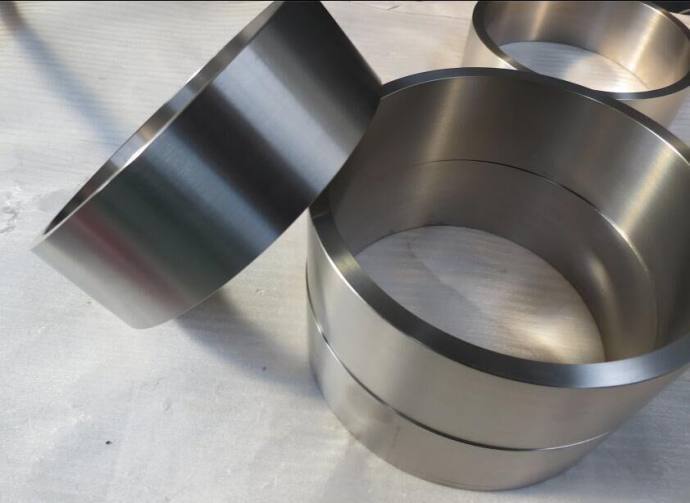

TC11(Ti-6.5Al-3.5Mo-1.5Zr-0.3Si) titanium alloy parameters.( titanium sheet ams 4911)

TC11(Ti-6.5Al-3.5Mo-1.5Zr-0.3Si) belongs to the national standard titanium alloy, the implementation standard: GB/T 2965-2007;

The nominal composition of TC11 titanium alloy is Ti-6.5Al-3.5Mo-1.5Zr-0.3Si, which is an α-β type titanium alloy heat-resistant titanium alloy with an aluminum equivalent of 3.5 and a molybdenum equivalent of 7.3.

The alloy also has good hot working processability (including conventional process performance and superplasticity), and can be welded and machined in various ways.

Beta heat treatment and isothermal forging of this alloy have been developed rapidly. The alloy also has a certain sensitivity to hot salt stress corrosion.

The alloy is mainly used to manufacture parts such as compressor discs, blades, drums and other parts of aero engines, and it can also be used to manufacture aircraft structural parts.

Through the thermal deformation and heat treatment in the α-β zone, the maximum long-term working temperature of the alloy is 500°C. The semi-finished products produced include bars, forgings and die forgings. TC11(Ti-6.5Al-3.5Mo-1.5Zr-0.3Si ) titanium alloy is a high-temperature titanium alloy widely used in China's aviation industry, with a maximum operating temperature of 500°C. It is mainly used in the components of aero engine compressors, such as blades, discs, drums and shafts.

It can also be made into special-shaped castings. The working conditions of the parts are: 500 hours below 500°C, 100 hours below 550°C and 1000 hours below 450°C in the annealed state, and 100 hours work below 500°C in the strengthened state Parts and parts that work at a time below 700°C.

buy titanium plate,craniotomy titanium plate,titanium foil sheet.how to cut titanium sheet.