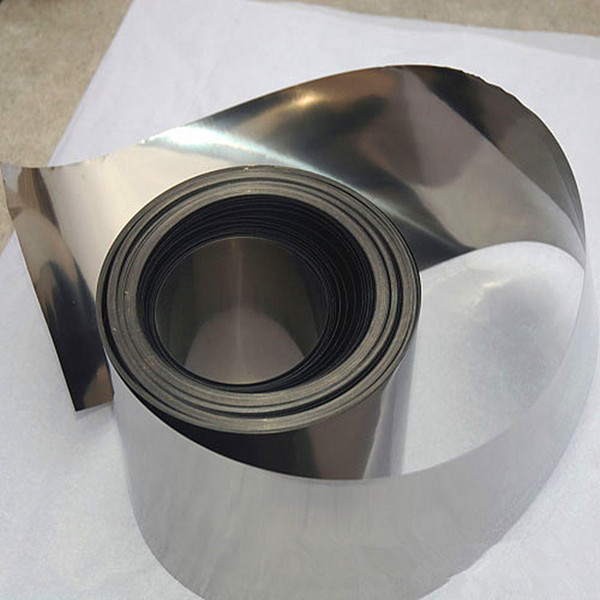

Development and application market of low-alloy titanium coils.

As my country started late in the development of titanium coil products, it was not until the national "Eleventh Five-Year Plan" period of this century that construction began. So far, the key technology of low-alloy titanium coil production is still mastered by several large foreign titanium coil manufacturers. A domestic enterprise has only begun to conduct in-depth research in recent years and has made preliminary progress. However, domestic low-alloy titanium coils still need to be imported in large quantities each year, and their prices and demand are controlled by people, in order to suppress and stifle the production of domestic low-alloy titanium coils, so as to achieve the purpose of exporting titanium processed products to China and monopolizing the market.

Alloy titanium strip coils are mainly used in high-tech fields such as aircraft, spacecraft, submarines, nuclear power plants, medical treatment, high-end racing, and civil fields such as metallurgy, chemical industry, and decoration.

At present, a number of complete titanium coil production lines have been built in China, and they have begun to take shape. The equipment strength has far exceeded that of similar foreign manufacturers. In November 2008, with the successful trial production of domestic cold-rolled titanium coils, a complete production chain from sponge titanium, smelting, forging, rolling, finishing treatment, and deep processing was formed. The production technology of titanium coils has been improved day by day, and a lot of data and experience have been accumulated for the production of low-alloy wide-width titanium coils.

Medical industry

Due to the excellent compatibility of titanium with the human body, it has always been the material of choice in the medical industry. With the development of the strip market, the medical industry, which previously relied on sheet production to provide raw materials, began to tend to replace it with strip production, mainly considering the high precision and high consistency of strip production, which can fully ensure the use of the human body. However, at the same time, a slightly higher strength index requirement is also put forward, which also promotes the potential of the low alloy market.

civil market

In recent years, due to the promotion of titanium for construction and kitchenware, the use of titanium in the civilian market has gradually been accepted by people. Everyone has begun to take the proportion of titanium in life as a corporate propaganda strength. In emerging markets such as mobile phone cases, laptops, business card holders, and even business cards, titanium has gradually become a propaganda tool and a carrier of information transmission.

pipe

Ti-3Al-2.5V is mainly used as a seamless pipe application. The tube can be processed into various crystal directions from radial texture to axial texture. The variety of textures of Ti-3Al-2.5V provides an effective way to improve performance. Ti-3Al-2.5V was originally developed as a material for welded pipes and seamless pipes. Later, this alloy was also used in other structures, but the current pipe application still dominates.

Now practically all commercial airliners have Ti-3Al-2.5V hydraulic systems, and this alloy is increasingly used in chemical equipment. The chemical equipment made of it can withstand higher operating temperatures, improve efficiency, and significantly reduce environmental impact, especially its good corrosion resistance in seawater, making it gradually used in seawater cooling systems and subsea oil extraction. At the same time, high strength, low density and good rigidity are excellent materials developed for bicycle frames and golf clubs.

Besides titanium strip in medical sides.And also titanium surgical plates:Such as titanium plate in wrist,titanium plate heart surgery,titanium mesh plate skull.