Home / All / Titanium Processing / Titanium Plates / Titanium Strip Plates /

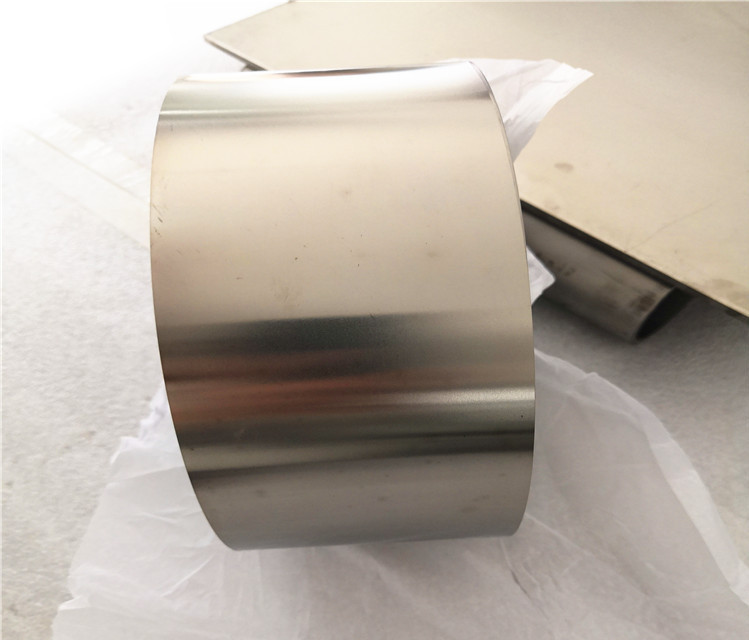

Gr7 titanium alloy strip with astmb265 used for electroytics plating

Gr7 titanium alloy strip with astmb265 used for electroytics plating

Detail Information

All of our titanium strip according ASTMB265,ASTMF67 produced,We both manufacture titanium alloy strip and pure strip,and our titanium strip price is good.our titanium strip for sale to customers with high quality.

Chemical composition

Grade | Chemical composition, weight percent (%) | ||||||||||||||

|

C ≤ |

O ≤ | N ≤ |

H ≤ |

Fe ≤ | Al | V |

Pd |

Ru | Ni | Mo | Other Elements Max. each | Other Elements Max. total | |||

Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | — | — | — | — | — | — | 0.1 | 0.4 | ||

Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | — | — | — | — | — | — | 0.1 | 0.4 | ||

|

Gr7 |

0.08 |

0.25 | 0.05 |

0.0015 |

0.30 | — | — |

— |

— | — | — | 0.1 | 0.4 | ||

|

Gr12 |

0.08 |

0.25 | 0.03 |

0.015 |

0.30 | — | — |

— |

— | 0.6~0.9 | 0.2~0.4 | 0.1 | 0.4 | ||

Physical properties

Grade | Physical properties | ||||||

|

Tensile strength Min |

Yield strength (0.2%, offset) |

Elongation in 50mm Min (%) |

|||||

ksi | MPa | Min | Max | ||||

ksi | MPa | ksi | MPa | ||||

Gr1 | 35 | 240 | 20 | 138 | 45 | 310 | 24 |

Gr2 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

|

Gr7 |

50 |

345 | 40 |

275 |

65 | 450 | 20 |

|

Gr12 |

70 |

483 | 50 |

345 |

— | — | 18 |

Tolerance (mm)

Thickness Size | Thickness tolerance | Width tolerance | |

500~900 | 900~1500 | ||

0.3~0.5 | ±0.05 | ±0.60 | ±1.0 |

0.6~0.7 | ±0.06 | ||

0.8~0.9 | ±0.09 | ||

|

1.0~1.4

|

±0.13

|

||

|

1.5~1.9

|

±0.16

|

||

|

2.0~2.4

|

±0.20

|

||

2.5~3.9 | ±0.22 | ||

|

4.0~5.0

|

±0.3

|

||

Testing :

Chemical composition test,

Physical properties test,

Appearance defects inspection,

Ultrasonic flaw detection,

Eddy current testing.

Chemical processing, medical instruments;

Aerospace, Industry, power plant;

Textile printing and dyeing;

Petrochemical industry;

Electroplating equipment;

Machining field, Automobile field;

Electroytics plating;

The equipment used in the sea water;

Features :

Conductive oxide surface film;

High corrosion resistance;

Low density, good thermal stability;

Non-ferromagnetic;

Surface promotes drop-wise condensation;

High temperature and low temperature resistance;

High resistance to strong acid and strong alkali and so on.

What we can do for you?

- If the above model is not suitable for your workpiece, please tell us your need and then we can send you the most satisfying drawing.

- contact us

Review

- Loading...

More than 10 year Foundry Operation Experience.

Committed to titanium processing and productionExported to +20 Overseas Countries.

- Tel

- *Title

- *Content

Titanium Custom Parts Manufacturing

NAVIGATION

More than 10 year Foundry Operation Experience.

Committed to titanium processing and productionExported to +20 Overseas Countries.

- Tel

- *Title

- *Content

Titanium Custom Parts Manufacturing

INFORMATION

- Tel:

0086-917-3323952

0086-15592563725

- WhatsApp:

- https://wa.me/8615592563725

- Skype:

- Skype:viresells2

- Address:

- Guojiacun Industry park,Maying Town,Weibin District,Baoji Shaanxi,P.R.China