Home / All / Titanium Processing / Titanium Forgings / Titanium Rings /

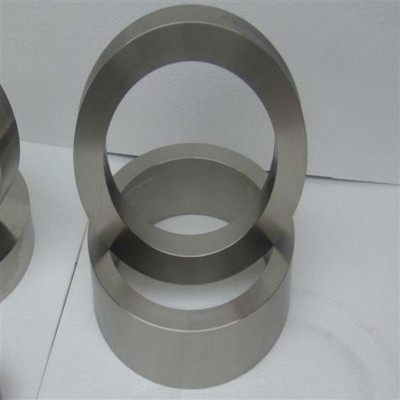

Gr2 forge titanium ring used in oil petroleum industry with compression and high temperature resistance

Gr2 forge titanium ring used in oil petroleum industry with compression and high temperature resistance

| Categories | Titanium Rings |

|---|---|

| Brand | MMR Parts Processing | Custom Parts Manufacturing |

| Grade | Gr1,Gr2,Gr3,Gr4,Gr5,Gr7,Gr9,Gr12 |

| OD | 200~1300mm |

| ID | 100-900mm |

| Technology | Forged, Cold-Rolled, Machining |

| Condition, Hot rolled(R), Annealed (M) | Annealed (M) |

| Surface | Pickling surface, machined surface, sandblast sur |

| Specifications | Aerospace, Chemical Industryl, Industrial |

| FOB port | shanghai,Tianjin |

| Terms of Payment | L/C, D/A, D/P, Western Union |

| Update Time | Jun 27,2025 |

Detail Information

We wre titanium forging supplier in this field for many years, some customer have a question,are titanium rings heavy? It denpends on the size. All of our materials will be strictly inspected and the quality is guaranteed . And we will supply materials test certificates after goods finished. The following infos are detailes about our materials.

|

Grade |

Gr1, Gr2, Gr3, Gr4, Gr5,Gr7,Gr9,Gr12,Gr23 |

||

Standard | ASTMB381 | ||

|

Technology |

Hot-Rolled, Cold-Rolled, Machining |

||

|

Surface |

Pickling surface, Polished surface, sandblasted surface |

||

|

Specifications |

Aerospace, Chemical Industry , Industrial

|

||

Chemical composition

Grade | Chemical composition, weight percent (%) | ||||||||||||||

|

C ≤ |

O ≤ | N ≤ |

H ≤ |

Fe ≤ | Al | V |

Pd |

Ru | Ni | Mo | Other Elements Max. each | Other Elements Max. total | |||

Gr1 | 0.08 | 0.18 | 0.03 | 0.015 | 0.20 | — | — | — | — | — | — | 0.1 | 0.4 | ||

Gr2 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | — | — | — | — | — | — | 0.1 | 0.4 | ||

|

Gr3 |

0.08 |

0.35 | 0.05 |

0.0015 |

0.30 | — | — |

— |

— | — | — | 0.1 | 0.4 | ||

|

Gr4 |

0.08 |

0.25 | 0.03 |

0.015 |

0.30 | — | — |

— |

— | — | — | 0.1 | 0.4 | ||

Gr5 | 0.08 | 0.20 | 0.05 | 0.015 | 0.40 | 5.5~6.75 | 3.5~4.5 | — | — | — | — | 0.1 | 0.4 | ||

Gr7 | 0.08 | 0.25 | 0.03 | 0.015 | 0.30 | — | — | 0.12~0.25 | — | — | — | 0.1 | 0.4 | ||

Gr9 | 0.08 | 0.15 | 0.03 | 0.015 | 0.25 | 2.5~3.5 | 2.0~3.0 | — | — | — | — | 0.1 | 0.4 | ||

Gr12 | 0.08 | 0.30 | 0.03 | 0.015 | 0.30 | — | 0.6~0.9 | 0.2~0.4 | 0.1 | 0.4 | |||||

Gr23 | 0.08 | 0.13 | 0.03 | 0.0125 | 0.25 | 5.5~6.5 | 3.5~4.5 | — | — | — | — | 0.1 | 0.4 | ||

Physical properties

Grade | Physical properties | ||||||

|

Tensile strength Min |

Yield strength (0.2%, offset) |

Elongation in 50mm Min (%) |

|||||

ksi | MPa | Min | Max | ||||

ksi | MPa | ksi | MPa | ||||

Gr1 | 35 | 240 | 20 | 138 | 45 | 310 | 24 |

Gr2 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

|

Gr3 |

65 |

450 | 55 |

380 |

80 | 550 | 18 |

|

Gr4 |

80 |

550 | 70 |

483 |

95 | 655 | 15 |

Gr5 | 130 | 895 | 120 | 828 | — | — | 10 |

Gr7 | 50 | 345 | 40 | 275 | 65 | 450 | 20 |

Gr9 | 90 | 620 | 70 | 483 | — | — | 15 |

Gr12 | 70 | 483 | 50 | 340 | — | — | 18 |

Gr23 | 120 | 828 | 110 | 759 | — | — | 10 |

Tolerance (mm)

OD | Tolerance | ID | Tolerance | Thickness | Tolerance | |||||

200~400 | +3 -1 | 100~300 | +1 -3 | 35~120 | +3 -1 | |||||

401~700 | +4 -2 | 150~300 | +2 -4 | 40~160 | +4 -2 | |||||

701~900 | +5 -3 | 300~700 | +3 -5 | 50~180 | +5 -3 | |||||

901~1300 | +6 -3 | 400~900 | +3 -6 | 70~250 | +6 -3 | |||||

Testing :

Chemical composition test,

Physical properties test,

Appearance defects inspection,

Ultrasonic flaw detection,

Eddy current testing,

Macroscopic examination.

Aerospace, Industry, Navigation, artifical bones;

Textile printing and dyeing;

Sporting products;

Electroplating equipment;

Machining field, Automobile field;

Axis machining, the frame of the planes;

The equipment used in the sea water;

Heat exchangers and condensers;

Construction industry etc.

Features :

High tensile strength;

High corrosion resistance;

Low density, good thermal stability;

Non-ferromagnetic;

Good bio-compatibility;

High temperature and low temperature resistance;

High resistance to strong acid and strong alkali and so on.

What we can do for you?

- If the above model is not suitable for your workpiece, please tell us your need and then we can send you the most satisfying drawing.

- contact us

Related Products

Review

- Loading...

More than 10 year Foundry Operation Experience.

Committed to titanium processing and productionExported to +20 Overseas Countries.

- Tel

- *Title

- *Content

Titanium Custom Parts Manufacturing

NAVIGATION

More than 10 year Foundry Operation Experience.

Committed to titanium processing and productionExported to +20 Overseas Countries.

- Tel

- *Title

- *Content

Titanium Custom Parts Manufacturing

INFORMATION

- Tel:

0086-917-3323952

0086-15592563725

- WhatsApp:

- https://wa.me/8615592563725

- Skype:

- Skype:viresells2

- Address:

- Guojiacun Industry park,Maying Town,Weibin District,Baoji Shaanxi,P.R.China