Home / All / Titanium-clad Copper Processing / Titanium-clad Copper Bars /

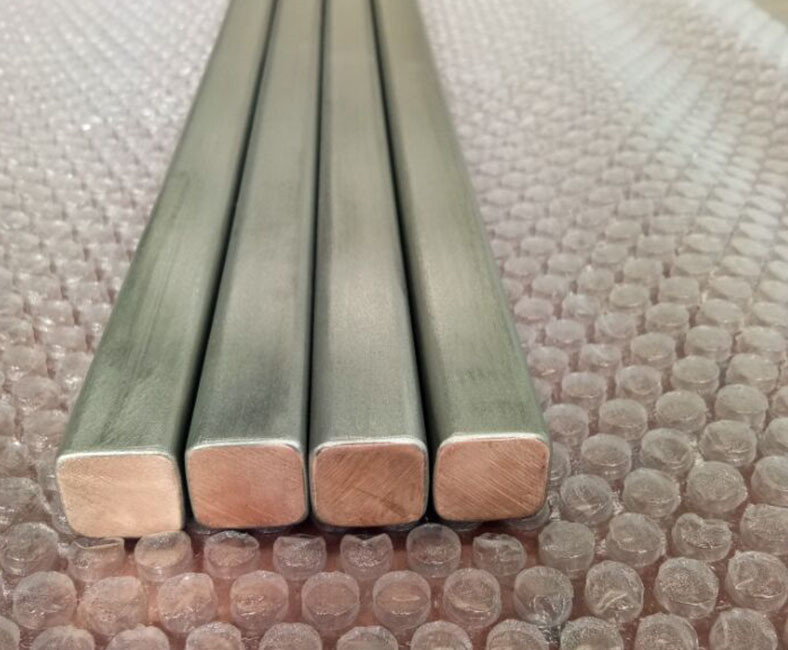

Three layers titanium clad copper rod for metal anode electrolyzer making

Three layers titanium clad copper rod for metal anode electrolyzer making

| Categories | Titanium-clad Copper Bars |

|---|---|

| Brand | MMR Parts Processing | Custom Parts Manufacturing |

| Base Materials | Pure copper |

| Clad material | CP titanium, Titanium alloy |

| Shape | Square, Round, Rectangular, Flat |

| Size | according to customer request |

| Technology | Rolled, Extrude, Stretching |

| Condition | Cold rolled(Y), Hot rolled(R), BM |

| Specifications | Electroplating, Electrolysis,l, Industrial |

| FOB port | shanghai,Tianjin |

| Terms of Payment | L/C, D/A, D/P, Western Union |

| Update Time | Apr 24,2025 |

Detail Information

AS a titanium clad copper bar manufacture,We can make grade 2 titanium rod with copper composite accordidng to customer size . The following are detail informations we always produce .

Here We have four production methods of titanium-copper composite rods are presented: hot extrusion method, hot extrusion + stretching method, explosion method, explosion + rolling method.

Cladding materials: titanium Ti, zirconium Zr, nickel Ni, stainless steel (304, 316L), etc.

Multilayer thickness: conventional 1.0~2.5mm

Main section shape and size range (mm):

Rectangular width (20~150)×thickness (6~30)

Round type Φ(8~50)

Square type side length (10~30)

Wire Φ(2.0~8.0)

Testing :

Chemical composition test,

Appearance defects inspection,

Tolerance detection.

Electrolysis, electroplating,

Electrolysis,PCB

Hydrometallurgy, power

Chemical industry,

Water treatment,

Ocean engineering, etc.

Features :

Low processing costs,

Big area of composite materials available with excellent metallurgical bonding by explosive welding process.

Copper Core and Great weldability for connecting, capping and joining,

Fantastic corrosion resistance in strongly corrosive solutions due to outside Titanium layer.

Excellent conductivity and fully ductile for shaping and forming due to OFHC (Oxygen-Free High Conductivity).

What we can do for you?

- If the above model is not suitable for your workpiece, please tell us your need and then we can send you the most satisfying drawing.

- contact us

Review

- Loading...

More than 10 year Foundry Operation Experience.

Committed to titanium processing and productionExported to +20 Overseas Countries.

- Tel

- *Title

- *Content

Titanium Custom Parts Manufacturing

NAVIGATION

More than 10 year Foundry Operation Experience.

Committed to titanium processing and productionExported to +20 Overseas Countries.

- Tel

- *Title

- *Content

Titanium Custom Parts Manufacturing

INFORMATION

- Tel:

0086-917-3323952

0086-15592563725

- WhatsApp:

- https://wa.me/8615592563725

- Skype:

- Skype:viresells2

- Address:

- Guojiacun Industry park,Maying Town,Weibin District,Baoji Shaanxi,P.R.China